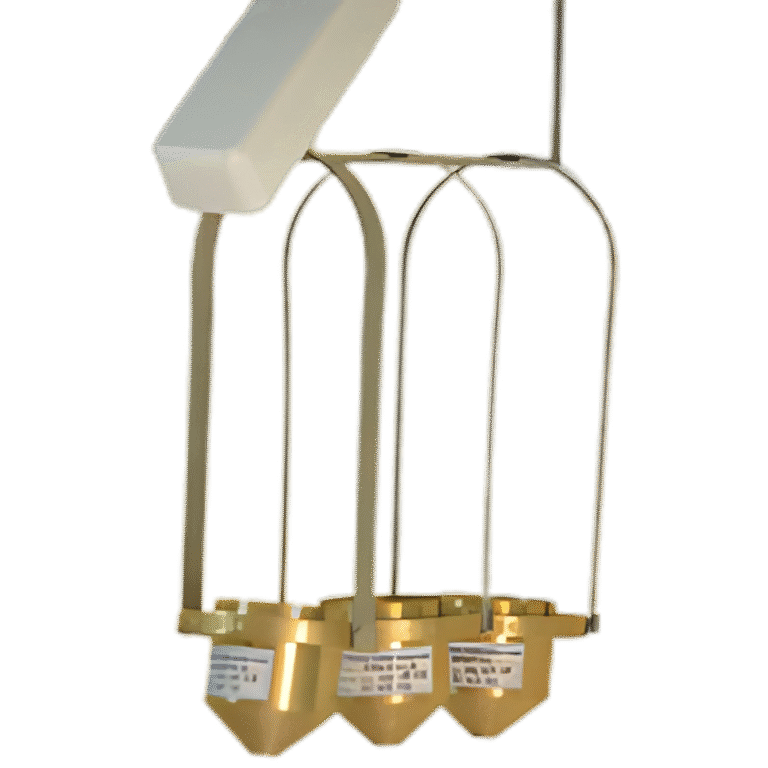

Viscosity Cups

Description:

In the Printing and Packaging industry, efflux cups commonly known as viscosity cups are vital tools for measuring the viscosity and flow properties of inks, coatings, and other liquid formulations used in the production process. These properties play a crucial role in ensuring consistent quality, proper application, and effective drying times for the printed materials.

Key Features:

Ink Viscosity Testing:

Ink Consistency:

- In printing, the viscosity of the ink must be carefully controlled to ensure smooth printing, proper color density, and accurate reproduction.

- If the ink is too thick (high viscosity), it will not flow properly through the printer’s rollers and plates.

- If it’s too thin (low viscosity), it might spread too easily, leading to issues like smudging or poor print quality.

Efflux Cups for Quality Control:

- Efflux cups like Ford cups are commonly used to measure the viscosity of inks before they are applied.

- The time it takes for the ink to flow through the efflux cup can help operators adjust ink formulations to meet the desired consistency.

Coatings and Finishes:

Surface Coatings:

- In the packaging industry, various coatings are applied to printed materials for purposes like gloss, protection, or adhesion.

- Efflux cups can be used to measure the viscosity of these coatings to ensure they are applied evenly and consistently.

- This is important for the final product’s appearance and durability.

Testing Coating Viscosity:

- Similar to ink testing, the viscosity of coatings influences how easily they can be applied to a surface and how well they adhere or dry.

- Too thick of a coating could clog equipment or be uneven, while a coating that’s too thin might not offer the desired protection.

Consistency in Production:

Batch-to-Batch Consistency:

- In large-scale printing and packaging production, maintaining the same viscosity from batch to batch ensures that the quality and characteristics of the printed materials remain consistent.

- Efflux cups help monitor this consistency and ensure that each batch of ink or coating is up to specification.

Control over Printing Speed:

- Printing machines are designed to operate at specific speeds, and ink viscosity can directly influence the speed at which the ink is laid down on the material.

- If the ink is too viscous, it can slow down production or require more pressure to apply.

- Efflux cups are a quick and easy way to monitor this.

Regulatory Compliance and Quality Assurance:

Standardization:

- In industries like food packaging, pharmaceuticals, and cosmetics, the printing and packaging materials must meet strict regulatory standards.

- Efflux cups help manufacturers ensure that their inks and coatings conform to industry specifications for viscosity, preventing issues like contamination or improper labelling.

Compliance with Standards:

- Many printing and packaging operations adhere to specific standards such as ISO, ASTM, and TAPPI, which require the use of efflux cups to measure and maintain ink and coating viscosity.

- These standardized measurements help meet legal requirements and ensure product quality.

Real-Time Monitoring:

On-the-Fly Adjustments:

- Some printers use efflux cups in a more dynamic, real-time manner, testing ink viscosity during a print run and making adjustments if necessary.

- If the ink starts to behave differently (e.g., the viscosity changes over time due to temperature fluctuations), operators can make adjustments to maintain print quality.

Custom Formulations:

Tailored Ink and Coating Formulas:

- In some cases, packaging designers may need specific types of ink or coating to achieve particular effects or durability.

- Efflux cups help in testing these custom formulations, ensuring that they meet the desired characteristics before they are used in mass production.

Monitor and Control Ink Mileage/ Consumptions:

- By regular checking Ink viscosities in regular intervals as set in Standard Operating Procedures, Printers can monitor and control Ink Consumptions and Improve inks mileage.

Key Benefits:

- Efficiency: Quick viscosity measurement helps in making fast adjustments to maintain print quality.

- Consistency: Helps maintain consistent ink or coating quality across different batches and printing jobs.

- Cost-effective: Prevents waste by ensuring that only the correct ink or coating formulation is used, saving materials and time.

- Quality Control: Allows operators to monitor and adjust the viscosity to avoid printing defects and ensure high-quality results.

Types of Efflux Cups Used:

- Ford Cup: A common type used in the printing industry to measure ink viscosity. It’s simple to use, and the flow time can be related to the ink’s performance on a press.

- DIN Cup: The DIN cup is also used in the printing industry to measure ink viscosity, particularly in European markets.

- Zahn Cup: Often used for coatings and other liquid formulations, it measures the outflow time and is similarly used to assess viscosity. Zahn cup is commonly used to check viscosity of various coatings.

How it works:

Procedure:

- An efflux cup is filled with ink, and the time it takes for the ink to flow out through a hole at the bottom is measured.

- The time it takes for the ink to flow out is inversely related to its viscosity – thicker inks will flow out more slowly, while thinner inks will flow out faster.

1.

High Quality Machinery

2.

Fast Delivery & Reliable Service

3.

Spare Parts & Technical Guidance

4.