Ceramic Anilox Engravers (CAE)

Specifications:

Material: High-grade ceramic or chrome-coated steel base

Measuring Range: Line count: 60–1600 LPI (Lines Per Inch)

Finishing Type: Super-finished surface for precise ink release

Description:

CAE’s next-gen Black Pearl Ceramic Anilox Coating is one of the most advanced on the market, applied with precision using robotic plasma technology. It ensures even, high-quality coating with excellent energy transfer. Thanks to its super-hardened surface, it lasts up to 25% longer and resists scoring and damage better than standard coatings—offering durability you can count on.

Key Features:

Material Composition:

- Thermal sprayed ceramic or chrome layer on a steel or aluminum core

Thickness:

- Ceramic layer thickness typically ranges from 0.1 mm to 0.3 mm

Density:

- High-density cell structures for fine ink control

Temperature Resistance:

- Withstands up to 800°C (ceramic surface) during production and cleaning processes

Air Release Technology:

Special engraving patterns promote quick ink release and prevent air trapping

Designs like yCell and COBRA offer improved release characteristics for difficult inks

Applications:

Flexographic and gravure printing

Flexible packaging (films, laminates, foils)

Labels and corrugated board printing

Coating and lamination lines

Specialty printing with metallic or high-viscosity inks

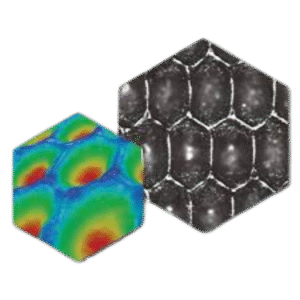

eCell Engraving

CAE’s eCell anilox technology gives you sharper prints and better consistency by transferring more ink with higher screen counts—without needing to change your plate screens.

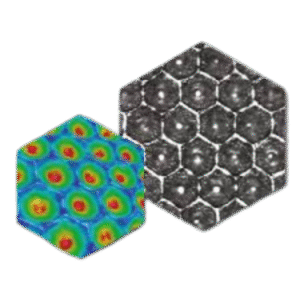

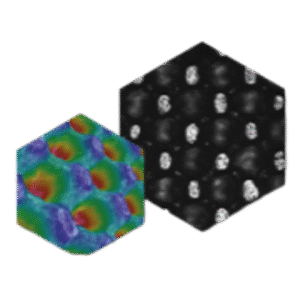

yCell Engraving

CAE’s advanced yCell anilox roller features a 60° hex design that ensures smooth ink release, better print quality, and longer roll life—while helping you save on ink.

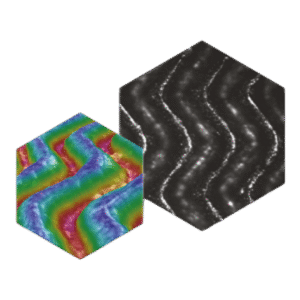

Cobra Engraving

Cobra’s unique open-cell design, inspired by a snake-like shape, allows smoother ink flow for richer color, better opacity, and sharper prints—plus, it’s easier to clean and lasts longer.

HITT Engraving

HITT ensures smooth, consistent ink transfer with its open-cell design—perfect for solid areas, opaque whites, lacquers, and coatings, even on offset and coating machines.