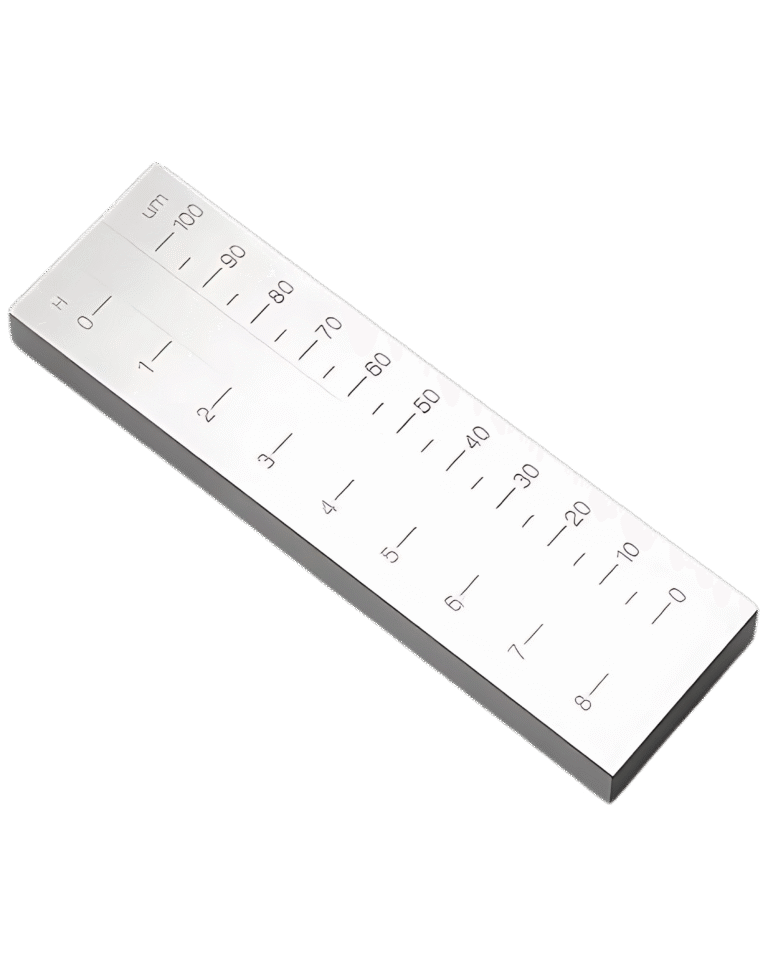

Grinding Gauge

Specifications:

- Width: 10 – 50 mm

- Color: Silver

- Material: Stainless Steel

- Grade: Industrial Grade

- Usage: Industrial and Laboratory Use

Description:

A Grinding gauge also known as a grind gauge or grindometer is a precision instrument used to assess the fineness of grind and detect the presence of larger particles or agglomerates within a dispersion. It plays a vital role in evaluating how finely particles (such as pigments) have been ground and dispersed in a liquid medium, commonly in industries like paint manufacturing. The particle size and dispersion level significantly influence the final properties and performance of the material.

The gauge is typically constructed from stainless steel and features a narrow channel with fine, parallel grooves that gradually decrease in depth from one end to the other. Next to the groove channel, a measurement scale is etched, indicating particle fineness. A standard Grinding gauge typically measures around 170 mm in length, 65 mm in width, and 15 mm in thickness. The groove channel is about 12.5 mm wide and tapers from a depth of 100 microns to zero.

Applications:

Oil Refineries

Marine Engineering

Textile Industry

Chemical Processing

Petrochemical Plants

Pharmaceutical Manufacturing

Mechanical Engineering

Nuclear Power Engineering