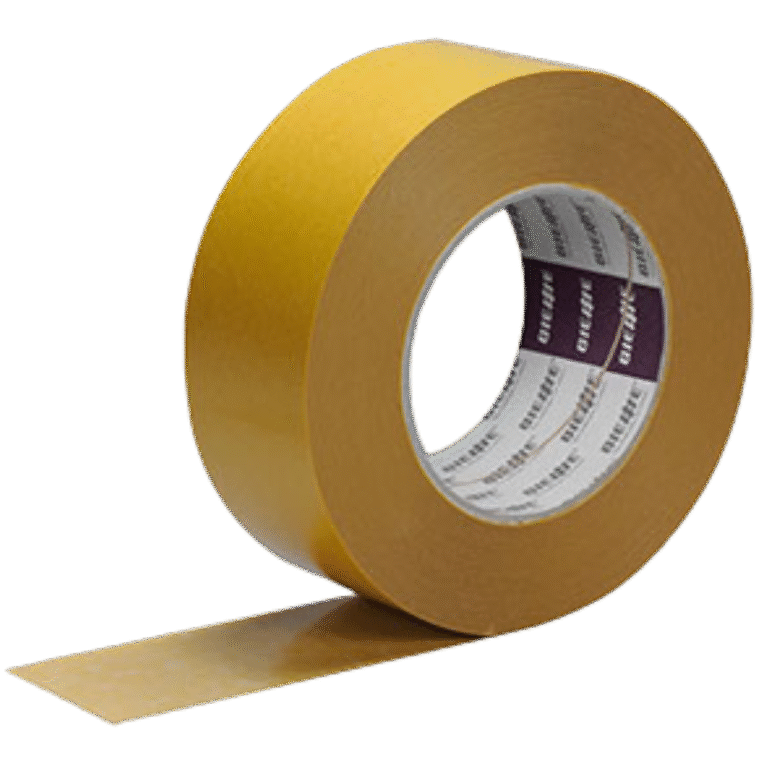

Biessse Splicing Tape

Specifications:

- Thickness: Typically ranges from 30 to 100 microns (varies by type).

- Width: Common widths include 12mm, 15mm, 19mm, 25mm, 50mm, and custom sizes.

- Tensile Strength: 50–150 N/cm (depends on backing material).

- Elongation at Break: 50–150% (for flexible applications).

- Adhesion Strength: 5–15 N/cm (peel strength, varies by adhesive type).

- Temperature Resistance:

♣ Standard: -10°C to 80°C

♣ High-Temp: Up to 180°C (short-term exposure).

Description:

Biessse (BiesSE) splicing tapes are widely used in the paper, printing, and packaging industries for joining materials during manufacturing processes.

Performance Features:

- High Tensile Strength: Ensures durability during high-speed splicing.

- Quick Stick: Instant adhesion for fast splicing operations.

- Low Residue: Clean removal without leaving adhesive behind.

- Chemical Resistance: Resists oils, solvents, and moisture (depending on type).

Material Composition:

- Backing Material: Polyester (PET), polypropylene (PP), or paper.

- Adhesive Type: Acrylic, rubber-based, or silicone (for high-temperature resistance).

- Release Liner (if applicable): Silicon-coated paper or film.

Types of BiesSE Splicing Tapes:

- BiesSE Standard Splicing Tape: General-purpose splicing for paper, film and foil.

- BiesSE High-Temperature Splicing Tape: For processes involving heat (e.g., printing, laminating).

- BiesSE Double-Sided Splicing Tape: Used where adhesion is required on both sides.

- BiesSE Non-Stick Splicing Tape: For applications requiring easy release.

Standards & Certifications:

- ISO 9001: Quality management compliance.

- FDA Compliance: Some grades may meet FDA requirements for indirect food contact.

- RoHS/REACH: Compliance with environmental regulations.

Storage & Handling:

- Store in a cool, dry place (15–25°C, 40–60% RH).

- Avoid direct sunlight and moisture.

Applications:

- Paper & Packaging: Splicing rolls in printing, corrugation, and converting.

- Film & Foil Converting: Joining flexible packaging materials.

- Labelling & Printing Presses: Web splicing in continuous printing.

1.

High Quality Machinery

2.

Fast Delivery & Reliable Service

3.

Spare Parts & Technical Guidance

4.